- HOME

- PRODUCT

Product Category

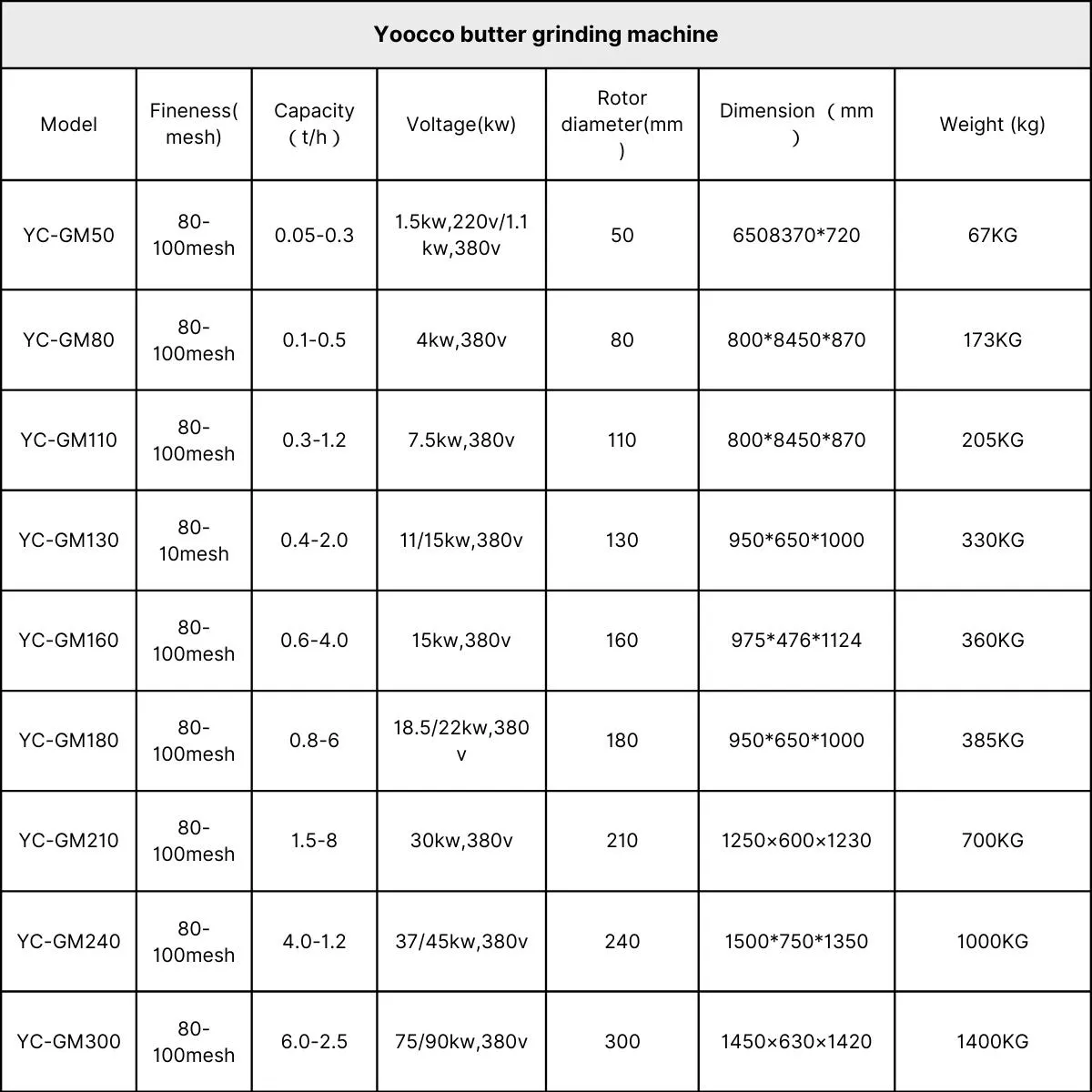

Butter Grinding Machines

Produce differents nuts butter.

Oil Pressing Machines

Hydraulic and screw oil pressing machine

Peeling Machines

Remove the red skin of the nuts.

Powder Grinding Machine

Milling the material for powder or small cakes.

Shelling Machines

Shelling differents nuts and grains.

See all products styles

Get inspiration from yoocco machine library.

Chocolate Making Machines

Complete Chocolate production Solutions

Peanut Brittle Machines

Complete peanut brittle solutions.

Cutting Machines

Cut the nuts for stripe,chope and slices.

Roasting Machiines

Roasting the nuts.

Frying and seasoning machines.

Frying and flavouring production line.

Note: We have’t covered all our offerings. Talk to our customer services teams for any Food processing machines needs. We are here to provide flexible and professional solutions.

Tell yoocco what material you want process and what you want get and how may kg/H. Then yoocco’s product expert will help you find suitable solutions.

- Solutions

- ABOUT US

Over 10 years experience

in manufacturing nuts processing machines

Case Study

The facts speak for themselves. Check out our fact-based flexible nuts processing solutions to see how well we’ve done in the past.

- RESOURCES

- CONTACT